Inkoni nziza ya Molybdenum, Bar ya Molybdenum, Molybdenum Electrode

Ibisobanuro

Ubwoko nubunini:

| Andika | Inkoni | Inkoni igororotse nyuma yo gushushanya | Inkoni zubutaka cyangwa imashini zirahari |

| Ingano | Ф2.4 ~ 120mm | Ф0.8 ~ 3.2mm |

Ibigize imiti:

| Ibirimo | Ibirimo byose mubindi bice | Buri Ibirimo |

| ≥99.95% | ≤0.05% | ≤0.01% |

Porogaramu

- Birakwiye kubyara ibice byo gutera ion.

- Kubyara amashanyarazi yumuriro nibice byamashanyarazi.

- Kubyara ibikoresho byo gushyushya nibice byangiritse mumatara yubushyuhe bwo hejuru.

- Ikoreshwa mu nganda n’ibirahure bya fibre, irashobora gukora igihe kirekire mumazi yikirahure yashonze kuri 1300 ℃.

- Ikoreshwa nka electrode murwego rwinganda zidasanzwe zisi.

Ubukorikori

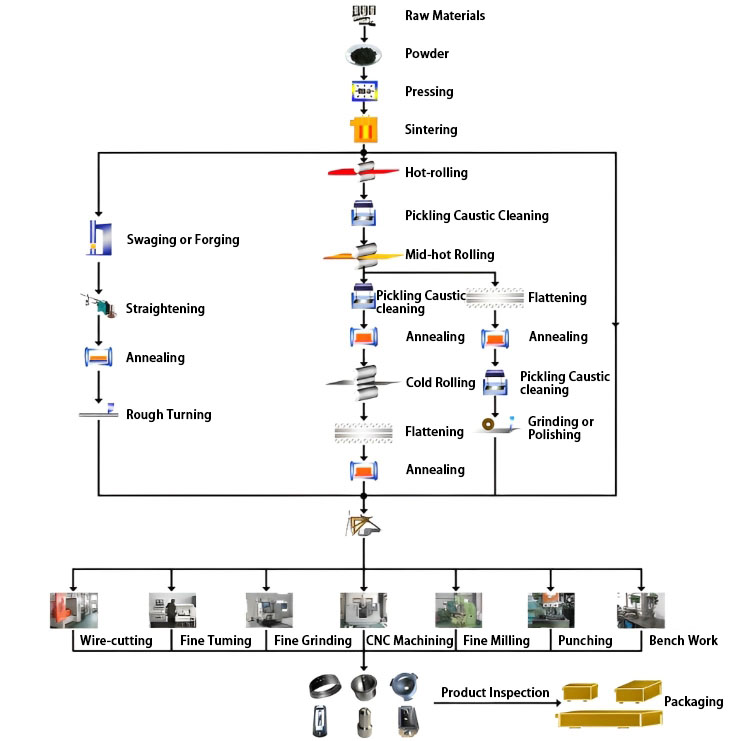

Ibikoresho bito:Duhereye ku bikoresho fatizo, duhitamo ibikoresho byiza byo mu rwego rwo hejuru, bigaragara cyane mu gutuza no guhuza ibicuruzwa.Menya ibirango bitandukanye byibikoresho fatizo hanyuma ushireho nimero yicyiciro.Kandi buri cyiciro cyibikoresho fatizo bigomba gutangwa, kugenzurwa no kubikwa.Menya neza niba buri gicuruzwa cyarangiye kandi uhore utezimbere ubuziranenge bwibicuruzwa.

Ifu:Igenzura ryogusya ibicuruzwa bya Zhaolinxin Ibyuma birasobanutse neza, hamwe nuruvange runini runini hamwe na vibrasiyo yo kunyeganyega kugirango harebwe niba ibikoresho biri murwego rwo kuvanga no kuvanga bishobora gukangurwa kandi bikagabanywa neza, kugirango habeho ishyirahamwe ryimbere guhuza ibicuruzwa.

Kanda:Muburyo bwo guhuza ifu, ifu ikanda nibikoresho byo gukanda isostatike kugirango imiterere yimbere yimbere kandi yuzuye.Zhaolixin ifite ibumba ryiza cyane, kandi ifite ibikoresho byo gukanda isostatike kugirango bihuze umusaruro wibicuruzwa binini cyane.

Icyaha:Muri powder metallurgie, nyuma yifu yicyuma ikozwe no gukanda isostatike, ishyuha mubushyuhe buri munsi yubushyuhe bwibice byingenzi kugirango ibice bihuze, kugirango bitezimbere imikorere yibicuruzwa, byitwa gucumura.Ifu imaze gushingwa, umubiri wuzuye uboneka mugucumura ni ubwoko bwa polycristaline.Inzira yo gucumura igira ingaruka itaziguye ingano yubunini, ingano ya pore nuburyo bwimbibi zimbibi no kugabura muri microstructure, aribwo buryo bwibanze bwa powder metallurgie.

Guhimba:Inzira yo guhimba irashobora gutuma ibikoresho bibona ubucucike buri hejuru, ibintu byiza bya mashini, kandi bikagira uruhare mugukomeza ubuso.Kugenzura neza igipimo cyo gutunganya no guhimba ubushyuhe bwibikoresho bya tungsten na molybdenum ni ikintu cyingenzi mu mikorere myiza ya Zhaolixin tungsten nibikoresho bya molybdenum.Uburyo bwo gutunganya bwo gukoresha imashini yo guhimba kugirango ushyire igitutu ku cyuma cyambaye ubusa kugirango uhindure plastike kugirango ubone impimbano ifite imiterere yubukanishi, imiterere nubunini.

Kuzunguruka:Inzira yo kuzunguruka ituma ibikoresho byuma bitanga umusaruro uhoraho wa plastike munsi yigitutu cyizunguruka, kandi ukabona imiterere nigice gikenewe.Hamwe na tekinoroji ya tungsten na molybdenum ikonje kandi ishyushye ikorana buhanga hamwe nibikoresho, kuva ibyuma bya tungsten na molybdenum byambaye ubusa kugeza kubyara tungsten na molybdenum foil, Zhaolixingu garanti yubuhanga buhanitse bwo gukora nibikorwa byiza byicyuma.

Gushyushya Ubushyuhe:Nyuma yo guhimba no kuzunguruka, ibikoresho bikoreshwa muburyo bwo gutunganya ubushyuhe kugirango bikureho burundu imiterere yimbere yimiterere yibikoresho, biha gukina imikorere yibikoresho, kandi byoroshe ibikoresho kugirango bikorwe nyuma.Zhaolixin ifite itanura ryinshi rya vacuum hamwe nogukoresha ubushyuhe bwa hydrogène kugirango huzuzwe vuba ibicuruzwa byinshi.

Imashini:Ibikoresho bya Zhaolixin byakorewe ubushyuhe bwuzuye, hanyuma bitunganyirizwa mubunini butandukanye byabigenewe hakoreshejwe ibikoresho nko guhinduranya, gusya, gukata, gusya, nibindi, kandi byemeza ko imitunganyirize yimbere yibikoresho bya tungsten na molybdenum bitoroshye, nta guhangayika. kandi nta mwobo, ushobora guhuza ibyo abakiriya bakeneye.

Ubwishingizi bufite ireme:Kugenzura no kugenzura ubuziranenge bizakorwa bivuye mu bikoresho fatizo na buri ntambwe y’umusaruro, kugirango bikomeze kwemeza ubuziranenge buri bicuruzwa.Muri icyo gihe, iyo ibicuruzwa byarangiye bitanzwe mububiko, isura, ingano hamwe nu muteguro wimbere wibikoresho bipimwa umwe umwe.Kubwibyo, gutuza no guhuza ibicuruzwa biragaragara cyane.